Cogeneration

A Modern Energy Solution for Greater Efficiency.

Introduction to Cogeneration

Cogeneration, also known as CHP (Combined Heat and Power), is an innovative energy generation technology that enables the simultaneous production of electricity and useful heat from a single fuel source. Unlike traditional power plants that waste a significant portion of the heat produced, cogeneration systems capture and effectively utilize nearly all of the thermal energy, thus increasing overall process efficiency. Notably, leading industry organizations such as ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) establish standards and guidelines for optimal building energy performance. At 3D ENERGY, we follow these guidelines to ensure that the solutions meet globally recognized best practices, guaranteeing the highest quality and effectiveness of the technologies we implement.

How Cogeneration Systems Work

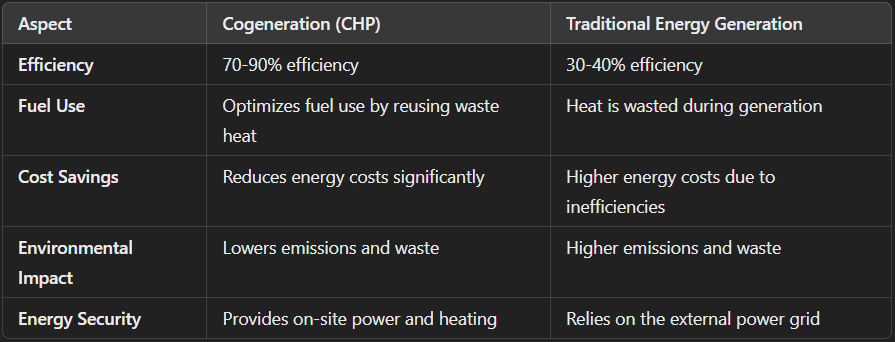

The foundation of cogeneration lies in maximizing the use of energy generated during electricity production. In conventional power plants, about 70% of energy is lost as waste heat. Our cogeneration systems recover this heat and direct it for heating water, buildings, or supporting industrial processes. By integrating ASHRAE recommendations, we maintain high standards of efficiency, comfort, and reliability, aligning with the top parameters for building quality. This approach allows us to achieve efficiencies of about 70-90%, compared to approximately 30% in traditional setups.

Fuel Versatility and Applications

One of the key advantages of our cogeneration systems is their flexibility in fuel selection. They can be powered by natural gas, LPG, diesel, biogas, biomethane, vegetable oil, or biomass. This versatility makes cogeneration suitable for various sectors—from small households to large-scale industrial facilities. Scalability enables installations from as low as 1 kW up to 1 GW. By combining this flexibility with ASHRAE’s guidelines for design and operation, we ensure that even complex and diverse installations operate with optimal efficiency while maintaining a high-quality indoor environment.

Types of Cogeneration Systems

At 3D Energy Tech, we offer several types of cogeneration solutions, each tailored to different facility needs:

1. Reciprocating Engine Cogeneration

• Best for industrial and commercial facilities, these systems use an internal combustion engine to generate both electricity and heat.

• Applications: Manufacturing plants, district heating, hospitals, and large office buildings.

• Benefits: High efficiency, quick installation, and flexible fuel options.

2. Gas Turbine Cogeneration

• These systems use gas turbines to generate electricity and recover waste heat.

• Applications: Large industrial facilities, power plants, and district energy systems.

• Benefits: Ideal for high electricity demand and large-scale applications.

3. Steam Turbine Cogeneration

•These systems use steam to generate electricity and recover heat for use in industrial processes or district heating.

• Applications: Industries with a constant need for steam, such as chemical plants, refineries, and paper mills.

• Benefits: Highly effective for facilities already generating steam for process purposes.

4. Micro-Cogeneration Systems

• Perfect for small-scale applications, micro-cogeneration systems use compact equipment, such as microturbines or Stirling engines, to provide heat and power for homes, small businesses, or remote locations.

• Applications: Small residential buildings, small commercial properties, remote off-grid locations.

• Benefits: Low maintenance, highly efficient, and cost-effective for small-scale needs.

Key Benefits of Cogeneration

Higher Energy Efficiency: By recovering waste heat, we can reduce fuel consumption by up to 40% compared to separate heat and power generation.

Lower Emissions: Reduced fuel consumption translates into decreased greenhouse gas emissions. It is estimated that cogeneration in Europe saves about 200 million tons of CO₂ annually.

Reduced Energy Costs: Using less fuel to produce the same amount of energy means lower operating expenses.

Reliability and Resilience: Our systems can operate close to the point of use, increasing energy security and minimizing transmission losses. By adhering to ASHRAE standards, we ensure seamless integration with building infrastructure, maintaining comfort and a healthy indoor environment.

Applications of Cogeneration Systems

Cogeneration systems are used in various industries and sectors, including:

• Manufacturing & Industrial Facilities: Reduce energy consumption and provide consistent, reliable power and heat for processes such as food processing, chemical manufacturing, and metal production.

• Hospitals & Healthcare Facilities: Improve energy reliability and efficiency, ensuring a continuous supply of power and heat for essential services.

• District Heating: Supply heating and electricity to entire communities, such as apartment complexes, universities, or commercial districts.

• Commercial Buildings: Hotels, office buildings, and retail spaces can benefit from cogeneration to reduce energy costs and enhance sustainability.

• Data Centers: Cogeneration can provide reliable power and cooling for data centers that require consistent, uninterrupted energy supply.

• Waste-to-Energy: Cogeneration systems can use waste products like biomass or municipal solid waste as a fuel source, turning waste into valuable energy.

Applications and Advanced Variants

Our cogeneration systems excel in industrial facilities, shopping centers, university campuses, hospitals, and district heating networks. Advanced versions include trigeneration (CCHP), where in addition to heat and electricity, cooling is also produced, as well as distributed generation—small, local installations that reduce transmission losses and strengthen energy infrastructure resilience. By following ASHRAE standards, we deliver solutions that not only stand out in terms of efficiency and sustainability but also integrate smoothly with building systems to provide optimal performance and user comfort.

Why Choose 3D Energy Tech for Cogeneration Systems?

• Tailored Solutions: Our team works closely with you to design a system that meets your facility’s unique energy needs.

• Comprehensive Design and Implementation: From initial assessment to system installation and ongoing optimization, we provide full-service support throughout the entire process.

• Energy Audits: As part of our service, we conduct thorough energy audits to ensure that a cogeneration system is the most cost-effective solution for your facility.

• Optimization & Maintenance: We offer continuous performance monitoring and regular maintenance to ensure your cogeneration system operates at peak efficiency throughout its lifespan.

• Sustainability Focus: Our cogeneration systems contribute to reducing your carbon footprint and support your facility’s sustainability initiatives.

Cogeneration vs. Traditional Energy Generation

Ready to Harness the Power of Cogeneration?

CHP systems offer unmatched energy efficiency and cost savings. Whether you are looking to optimize an existing facility or design a new one, our team at 3D Energy Tech can help you implement a solution that will enhance your building’s energy profile, reduce operating costs, and contribute to a sustainable future.

Summary

This solution is a forward-looking energy solution that combines high efficiency with lower costs and reduced environmental impact. Thanks to fuel flexibility and scalability, our cogeneration systems can be applied in a wide range of environments—from single-family homes to extensive industrial complexes. By maximizing energy use and minimizing heat loss, we place cogeneration at the heart of modern energy strategies. Furthermore, by adhering to ASHRAE guidelines, we ensure that our solutions meet global standards for building performance and indoor environmental quality, paving the way for more sustainable and resilient energy systems in the future.

Contact Us Today!

Reach out to us to discuss how cogeneration can transform your facility’s energy efficiency and sustainability efforts. Let us help you harness the power of both electricity and heat for a smarter, greener future.